How would the future look if buildings were to dynamically adapt to environmental conditions? If threads would show users how tightly they are stretched, e.g. for perfect suture after a surgery? If filters could clean themselves in factories?

Three renowned scientists, Prof. Jan Lagerwall from the University of Luxembourg, Prof. Maria Helena Godinho from NOVA School of Science & Technology and Prof. Eugene Terentjev from Cambridge University have recently received 8.4 million euros of funding from the European Research Council (ERC) to create and study liquid crystal elastomers (LCEs) of a new kind which enable such functionalities. The new LCEs originate from bio-sourced polysaccharides like cellulose, they will be recyclable and/or degradable as required, and they are highly responsive, changing color, shape, stiffness or damping properties in response to stimuli like heat, light, humidity or strain. This allows them to perform multiple functions, in highly diverse contexts. The project will also investigate new methods to process LCE precursors that are realistic for industrial upscaling.

By disrupting—in multiple ways—the conventional paradigm of how to make LCEs, the project will ensure that the new materials are eco-friendly, cost-effective, and ready for large-scale production. Through the project entitled “Atypical liquid crystal elastomers: from materials innovation to scalable processing and transformative applications” (ALCEMIST), the three researchers will thus unlock the full potential of LCEs.

Incredible potential of liquid crystal elastomers

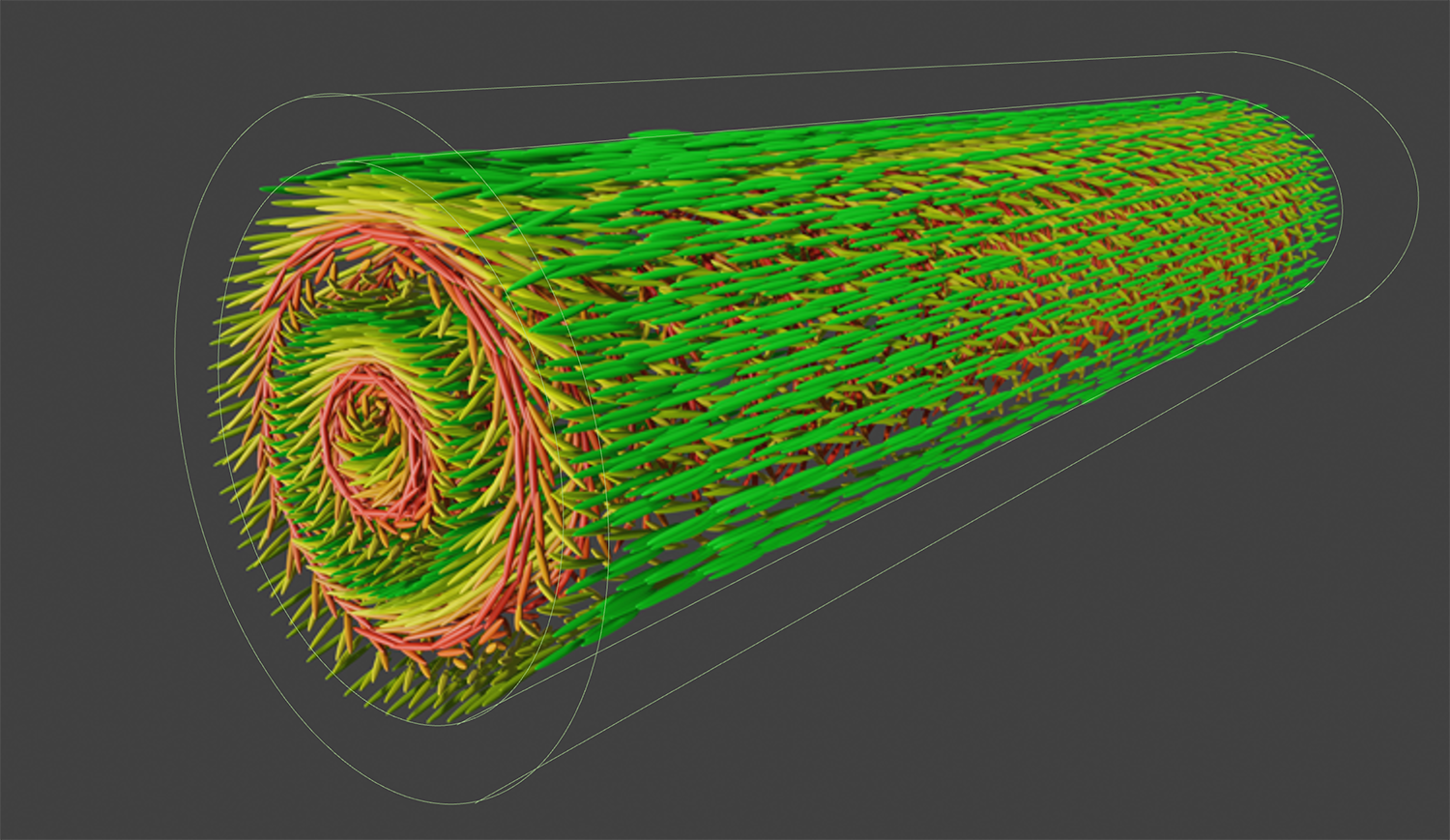

Liquid crystal elastomers are rubbers that extend and contract on their own. Like conventional rubbers, they can do mechanical work, but they require no externally imposed force to charge them. These materials have the potential to be used in various impactful applications, from energy-efficient engines to reversible adhesives, to adaptive buildings and advanced medical tools.

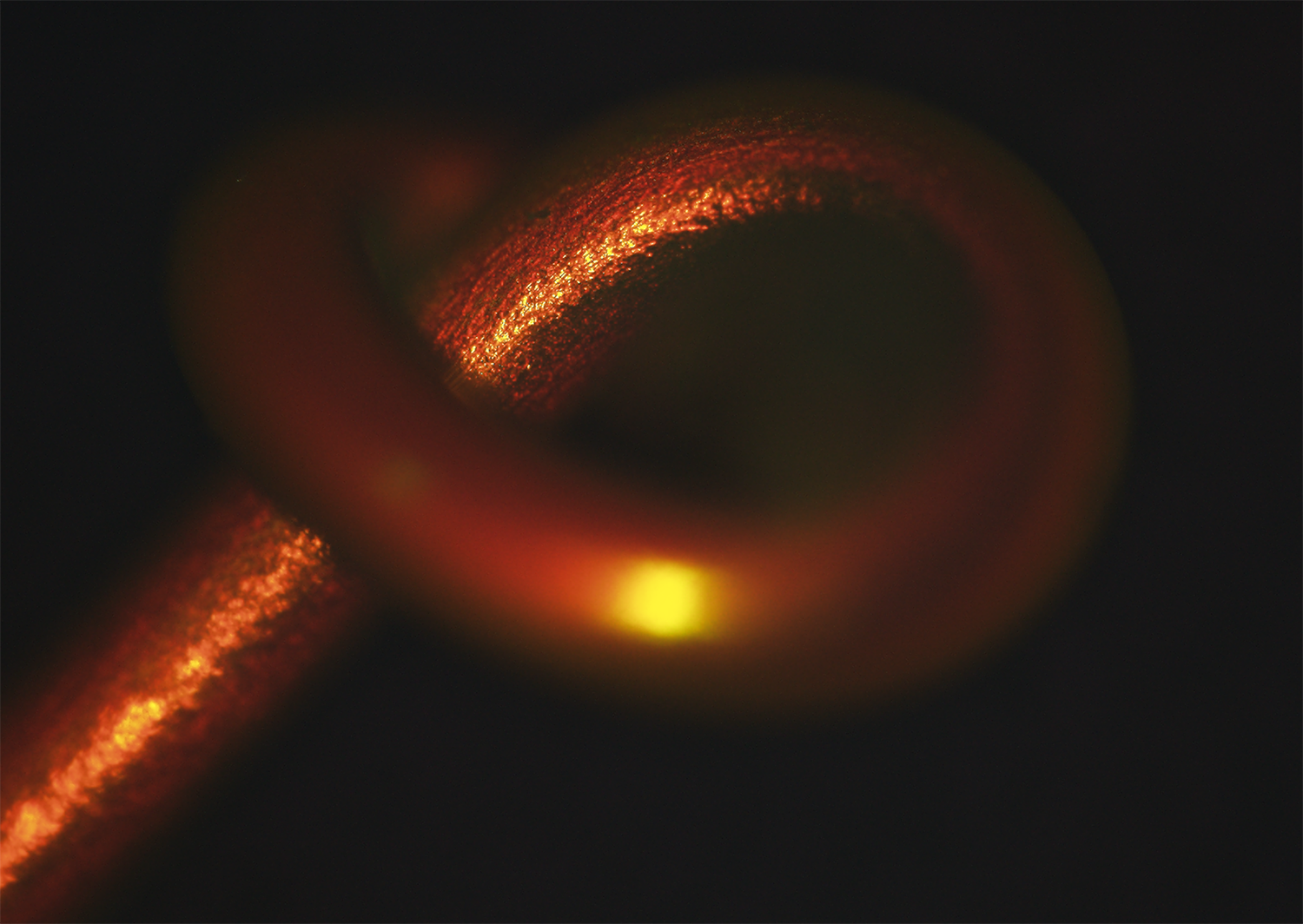

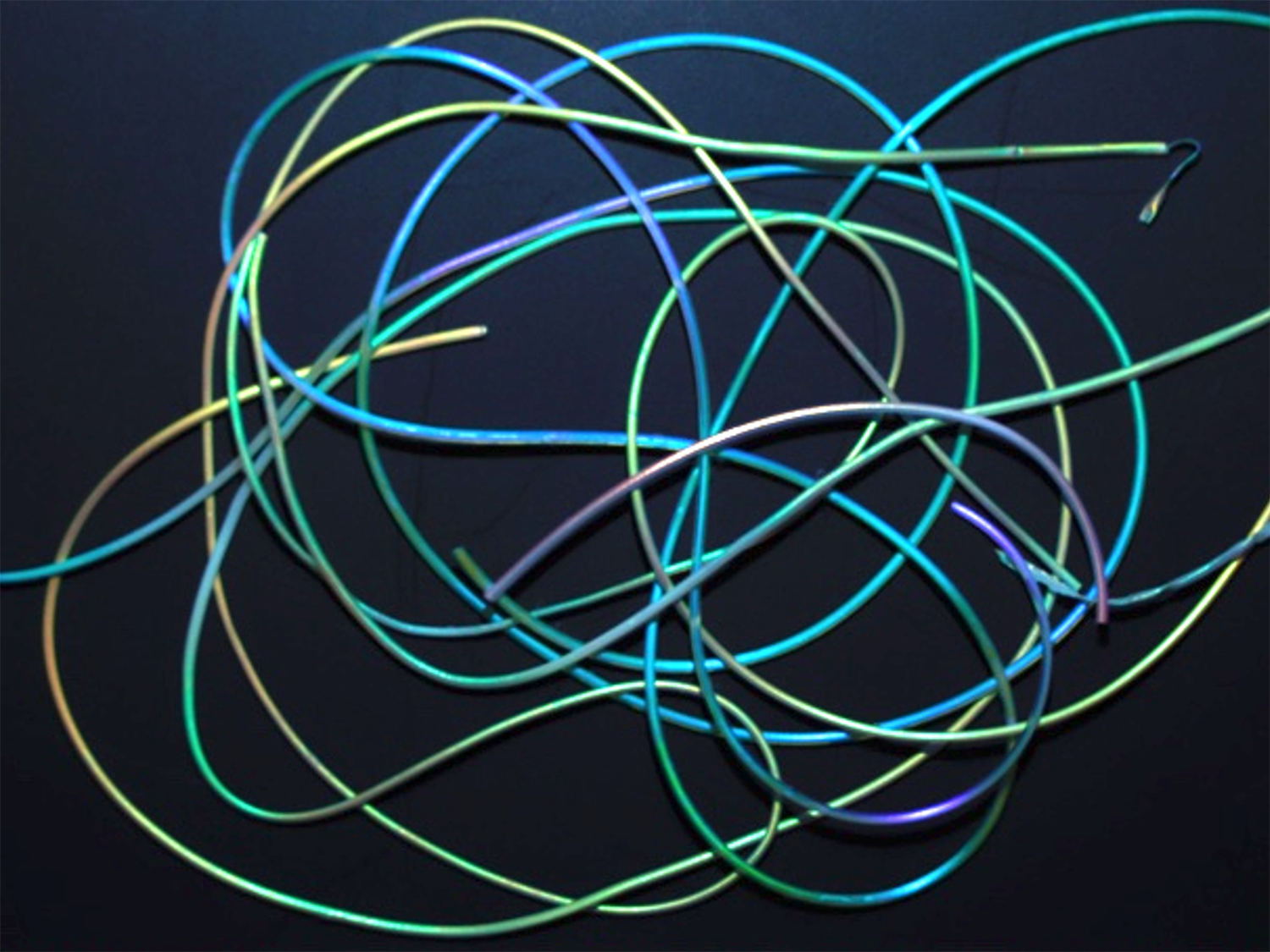

“We will demonstrate the potential of LCEs in six scenarios, selected for their striking broad impact, for instance heat engines running on industry waste heat, kinetic buildings that autonomously adapt to variations in environmental conditions, and suture threads that change colour upon stretching, ideal for robotic surgery”, comments Prof. Terentjev.

Making liquid crystal elastomers accessible

“In this project, we propose a new sustainable materials platform using natural substances called polysaccharides. By modifying these substances, like cellulose from plants or chitin extracted from seafood waste, anyone can create liquid crystal elastomers that are strong, safe for the body, and biodegradable, at a fraction of the current cost”, explains Prof. Godinho.

An application avenue of LCEs that was only recently discovered, by Terentjev, is in making reversible adhesives, which can be turned on or off on demand. This has huge potential for the circular economy since it will allow easy recycling of glued consumer products, from mobile phones to car windscreens. One of the main application-related goals of ALCEMIST is to develop this concept from the current first demonstrations of the phenomenon to materials that are ready for industrial scale-up.

First ERC Synergy grant in Luxembourg

This is the first time Luxembourg receives an ERC Synergy grant, and the University has the coordinating role. ALCEMIST will start in 2025 and run for six years. The Synergy Grant supports outstanding multidisciplinary scientists who join forces to answer major questions that cannot be answered by a single researcher.

Prof. Lagerwall is very excited about this project: “While LCEs were discovered in Europe, in terms of theory as well as in terms of the first materials, recent advances have given the field enormous momentum across a truly global arena.”

‟ With ALCEMIST we will ensure that Europe stays at the forefront, as we lead the transition towards making these amazing materials ready for large scale applications.”

Full professor in Experimental polymer physics

The ALCEMIST project challenges multiple conventions in the way LCEs are synthesised, studied and engineered, connecting polysaccharide chemistry, fluid mechanics, soft matter physics, and smart composites design. “Adding our ambition to make LCEs broadly accessible and propel them towards industrial production, ALCEMIST will enable creativity across large communities for a healthier and more sustainable future”, concludes Prof. Lagerwall.