About

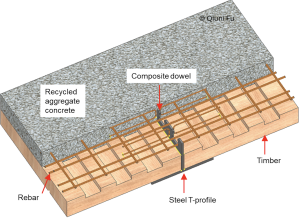

The construction industry is a major contributor to global resource consumption and CO₂ emissions, making it a prime target for circular economy strategies. This project, ReStart, introduces a novel hybrid slim floor system integrating steel, recycled aggregate concrete (RAC), and timber to enhance resource efficiency and reduce carbon emissions. The system utilizes puzzle-shaped composite dowels to connect RAC slabs with steel beams and incorporates timber as both permanent formwork and part of timber-concrete composite slabs. The overarching aim is to enable a reliable and cost-effective nonlinear design of slim composite beams using RAC, with particular attention to time-dependent effects due to creep and shrinkage. The research is structured into three main objectives: (1) characterizing the shear behaviour of steel-RAC composite dowels and developing a mechanics-based resistance model; (2) investigating the impacts of RAC creep on dowel performance and ultimate shear resistance under varying stress levels and loading sequences; and (3) assessing the strain-limited plastic resistance of composite beams using steel-RAC composite dowels at the cross-section and member levels, considering the influence of compact cross-sections with a steel T-profile and long-term effects. The project will deliver new knowledge and analytical tools — including a shear resistance model for steel-RAC composite dowels, reduction factor for long-term effects, a moment reduction factor at the cross-section level — along with design recommendations for strain-limited plastic (nonlinear) design of composite beams using composite dowels.

Organisation and Partners

- Department of Engineering

- Faculty of Science, Technology and Medicine (FSTM)

- Structural Engineering & Composite Structures (SECS)

Project team

-

Qiuni FU

-

Markus SCHÄFER