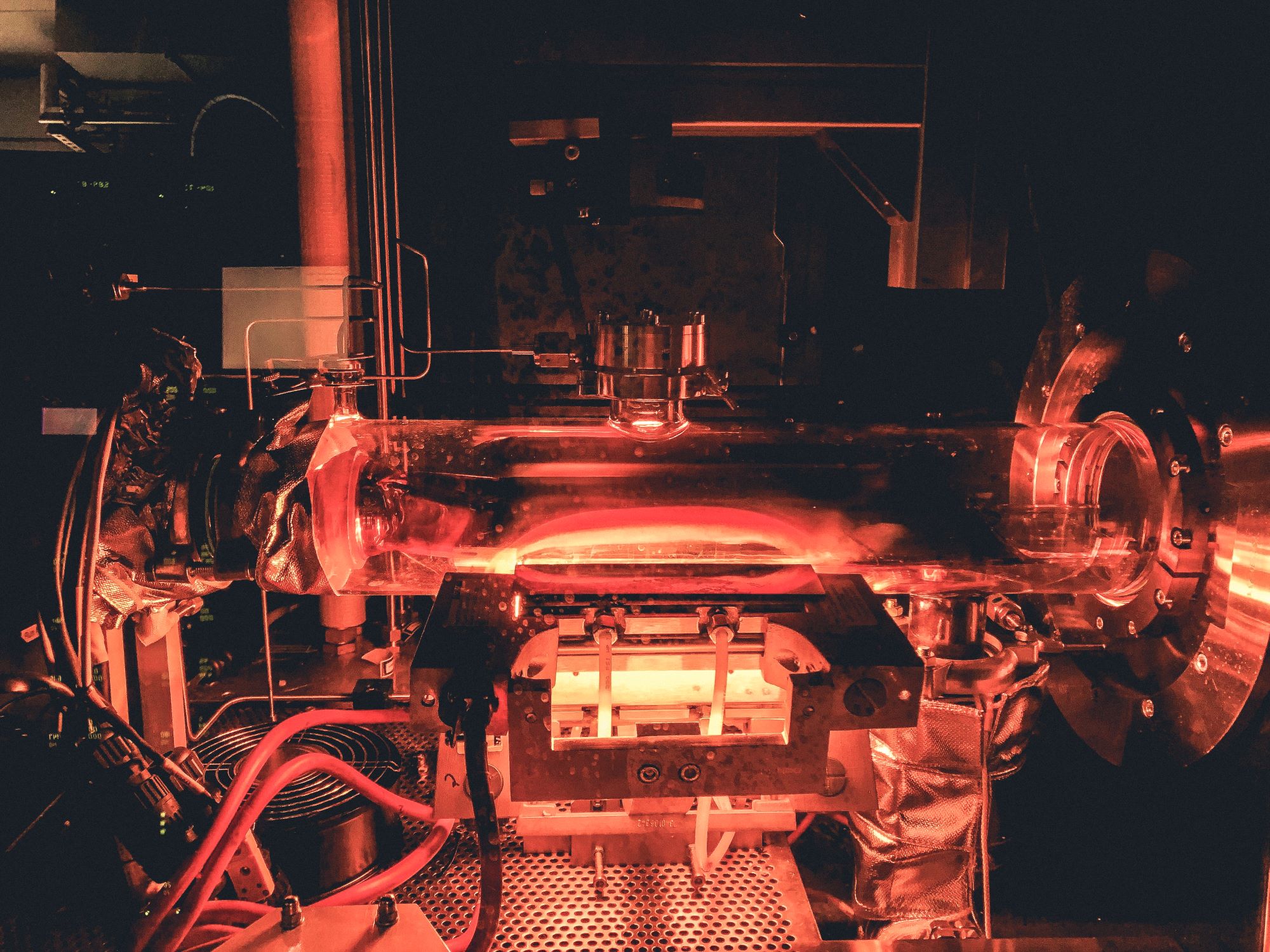

In our laboratory, we grow the absorbers for our solar cells completely from scratch, starting with a bare Soda-Lime substrate. To achieve this, we utilize three high-vacuum systems that allow for the co- evaporation of elements or compounds. Additionally, we use a tube furnace to anneal precursor films, and for the growth of epitaxial films, we rely on metal-organic vapour phase epitaxy (MOCVD).

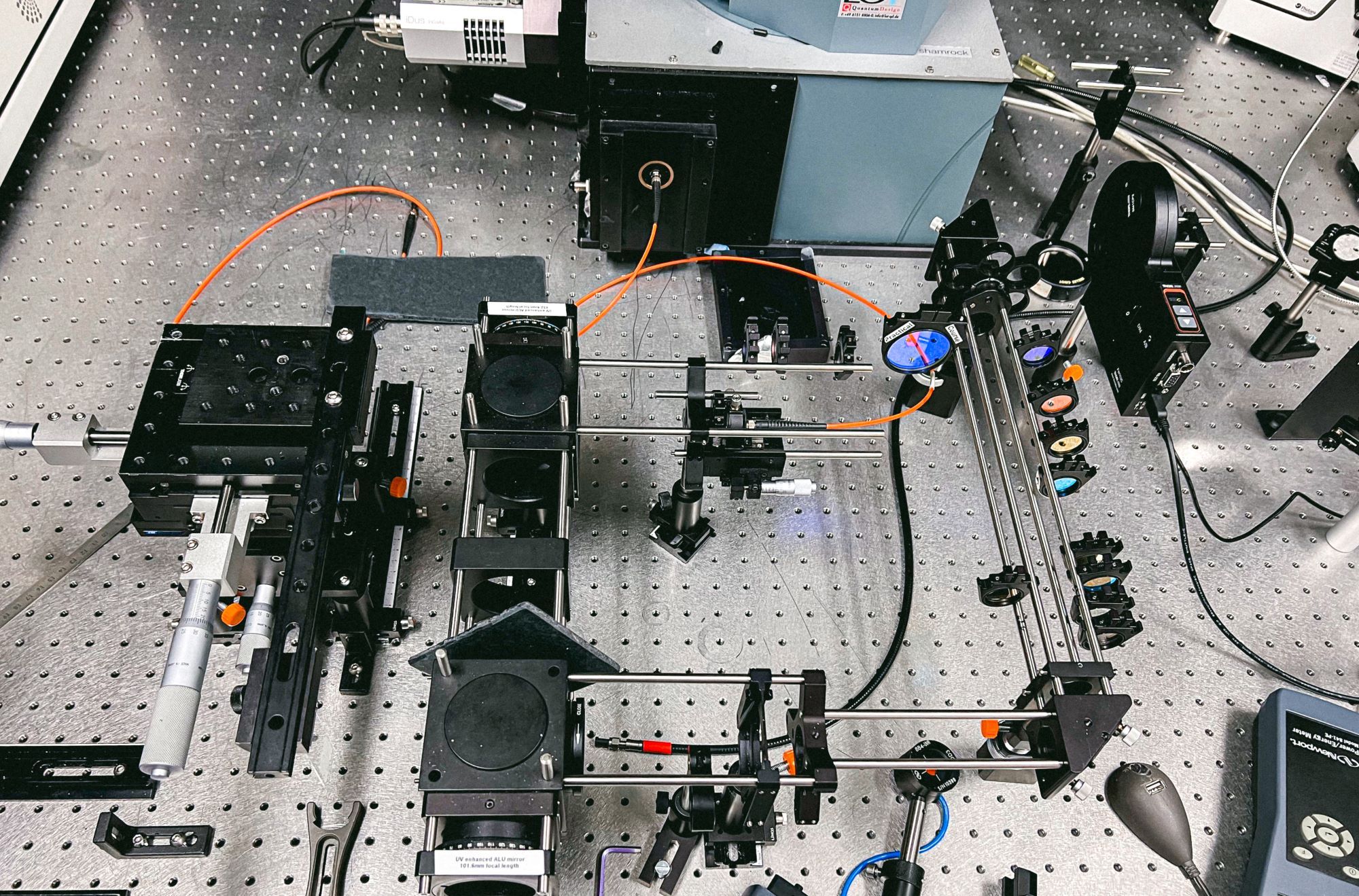

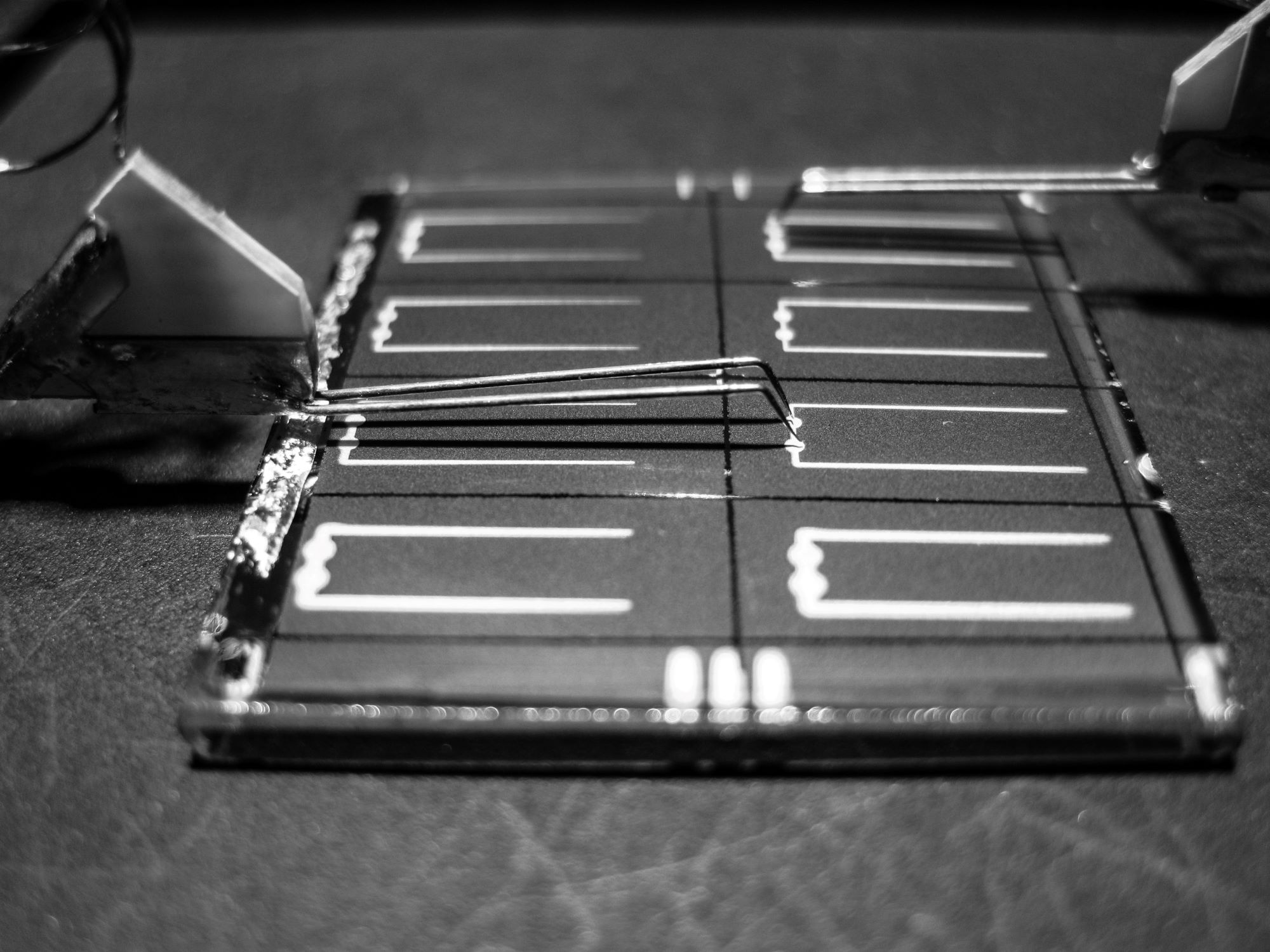

processes. We utilize a sputter machine for the metal backcontact, as well as for depositing the ZnO conductive window layer at the front of the cell. To create various buffer materials, we employ chemical bath deposition. Lastly, we use an electron beam evaporator for the deposition of metal grids.

Through these various techniques and machines, we are able to control the growth and composition of our solar cell absorbers to optimize their performance.