Programme

The Master in Sustainable Product Creation provides engineering students with a comprehensive understanding of the product creation process. It focuses on sustainable products and lays foundations on topics such as:

– Mechanical engineering

– Mechatronics

– Lean and sustainable use of resources

– Electrical engineering

– Computer networking

– Internet of things (IoT).

Semester structure

-

Common core (Mandatory)

No compensation between courses

Number of ECTS credits for this module: -

Mechanics (Elective)

S1 & S2: Prerequisites for the “Mechanics” module in the following semester

No compensation between coursesNumber of ECTS credits for this module: -

Electrical and Computer Engineering, ECE (Elective)

S1 & S2: Prerequisites for the “ECE” module in the following semester

No compensation between coursesNumber of ECTS credits for this module:

Academic Contents

Course offer for Semestre 1 (2025-2026 Winter)

-

Details

- Course title: Project management

- Number of ECTS: 4

- Course code: MSPC-1

- Module(s): 1.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Getting familiar with the basics of project management.

-

Course learning outcomes

Being able to organize projects, scope planning,scheduling , risk management and the related activities to set up a PM team. -

Description

History of PM, Basic PM definitions&standards, PM Processes, Time scheduling, Human factor in PM, establishing teamwork, leadership and conflict solving, future of PM work.

-

Assessment

Written exam (100%) -

Note

Literature resourcesScriptum of Lecture and related exercises (will be submitted during the lecture), participation in both block lectures and integrated exercises is mandatory for the examination.

-

Details

- Course title: Programming for engineers I

- Number of ECTS: 4

- Course code: MSPC-2

- Module(s): 1.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Understanding the MATLAB environment.

Being able to do execute codes/files using MATLAB.

Being able to carry out simple numerical computations and analyses using MATLAB.

-

Course learning outcomes

After attending this class, the students will be able to write algorithms with functions and scripts to solve engineering problems. The students can solve mathematical problems and manipulate matrices and vectors. They will learn the differences between scripts and functions. They will learn the repetitive and condition statements. The students can build a Graphic User Interface (GUI) They will acquire skill on data plotting, animation and 3D graphics. -

Description

Introduction to concepts of programming

Datatypes and Variables

Operators and Expressions

Loops

String Manipulation

Plotting/Data Visualization in 2D and 3D

GUI

-

Assessment

Continuous Evaluation via Homework (40%)Continuous evaluation will be made via homework exercises to be submitted regularly during the course.

There would be 3 homework assignments, each with the same weight on the evaluation.

The homework will programming questions.Grades will be awarded based on the solution obtained, the quality of code and the efficiency of the program.

Final Individual Project (60%)A MATLAB project incorporating the concepts taught during the lecture.

The assessment will be done based on

The complexity of the topic selected to submit as project

The quality of code (efficiency, readability and executability) -

Note

Literature resources

The course notes and slides will be provided during the lectures. Additional resources will be given during the lecture.

-

Details

- Course title: Supply chain & logistics

- Number of ECTS: 4

- Course code: MSPC-3

- Module(s): 1.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Provide knowledge and insight into supply chain systems as a whole (manufacturing, distribution, retail and customer demand), understand the critical infrastructure for the production and distribution, understand decision making issues in logistics and supply chain management in general and in terms of sustainability, understand the opportunities and constraints of digitalization in supply chain management (internet of things, digital documents, monitoring and alerting), apply conceptual, analytical and numerical tools for modeling and solving logistics and supply chain applications, give insight into network economics and system dynamics in supply chains.

-

Course learning outcomes

At the end of the course, students are able to explain the role and the meaning of logistics and supply chain systems in modern sustainable production and logistics networks, to describe the relations between the different players and how these systems work from supplier to customers, to manage simple networks in terms of efficient and green value creation in order to maximize the overall profit in the system, to apply both basic operational and strategic methods of supply chain management. -

Description

Introduction (basic concepts and definition), Strategic fit (make-or-buy, cost, responsiveness, agility), Supply Chain integration (material flow, push/pull and lead time concept), Facility location problems, Vehicle routing problems (e.g. travel salesman problem), Supply chain network design and equilibrium, Systems dynamics and value of coordination, Transport and distribution, Forecasting, Sales and Operations Planning, Capacity and Inventory Management, Material Requirements Planning , SCM policies and performance indicators, Sustainability and Reverse logistics, Digitalization in SCM. -

Assessment

Written exam (100%)Assessment based on written answers to a test using instructional tasks or questions (short question tests, case studies, essays), composed during 90 minutes of time on-site at the end of the term. Any language dictionary as well as a non-programmable calculator will be allowed during the exam.

-

Note

Literature resourcesChopra, S. (2019): Supply Chain Management: Strategy, Planning, and Operation, 7th ed., Upper Saddle NJ, Pearson, Boston, 2019

Christopher, M. (2022): Logistics Supply Chain Management, 6th edition, FT Publishing International, Upper Saddle NJ, 2022

Krajewski, L., Malhotra, M. (2024): Operations Management: Processes and Supply Chains, Global Edition, 14th edition, Pearson, Harlow/England, 2024

MacCarthy, B., Ivanov, D. (2022): The Digital Supply Chain, 1st edition, Elsevier, Amsterdam, 2022

Jacobs, F. R., Chase, R. B. (2018): Operations and Supply Chain Management, 15th Global Edition, McGraw-Hill Education, New York, 2018

Simchi-Levi, D., Kaminsky, P., Simchi-Levi, E. (2008): Designing and managing the supply chain, 3rd edition, McGraw Hill, New York, 2008

Articles from literature

Hand-outs

-

Details

- Course title: Life Cycle Assessment and Eco Design

- Number of ECTS: 3

- Course code: MSPC-4

- Module(s): 1.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Students of this course learn to design products/megastructures following the principles of sustainability. For that, students get to know what sustainable products and sustainable resources can mean. Additionally, students understand how a product’s performance for sustainability can be assessed in order to critically reflect on it. Particularly, the course aims at enabling students to apply life cycle assessment (LCA) and eco-design methods.

-

Course learning outcomes

After successfully participating in the course, students will be able to

1.) independently improve the environmental performance of their products/megastructures and developing sustainable product concepts by applying eco-design strategies, principles and methods in the early stages of the development process,

2.) integrate the ecological perspective in the technical product creation, and

3.) conduct their own LCA studies.

-

Description

The content of the course focuses on the following main areas:

– Introduction to sustainable development and related concept;

– The importance of life cycle thinking;

– The life cycle of products, services and megastructures;

– Environmental impacts and their indicators;

– Eco-design strategies, principles and methods;

– Manual calculation of LCA;

– Practical issues of LCA;

– Critical review of LCA studies;

– LCA and eco-design in early stages of the development process.

-

Assessment

Quiz 1 /

Written exam (33.33%)Quiz 2 / Written exam (33.33%)

Quiz 3 / Written exam (33.33%)

- Objective of the assignments: apply theoretical knowledge (concepts, categories) from previous lectures.

- Assessment criteria: correct choices in quizzes with various question types.

- Assessment rules: positive points for correct choices, negative points for wrong choices; each question is weighted equally.

-

Note

Baumann, H; Tillman, A-M: The Hitch Hiker’s Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Applications. Professional Pub. Service 2004

Literature resources

Crul, M.R.M; Diehl J.C: Design for Sustainability: A Step-by-Step Approach. United Nations Environment Programme 2009

-

Details

- Course title: Assembly and testing technologies

- Number of ECTS: 4

- Course code: MSPC-5

- Module(s): 1.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

The automotive industry is leading in advanced assembly and testing technologies.

The student will understand assembly, testing and adjustment processes at a vehicle final assembly plant and be able to apply this knowledge to future engineering tasks.

-

Course learning outcomes

The student will understand assembly technologies und related testing and adjustments regarding the requirements of the vehicle. They can evaluate product design for assembly. The students know machinery and equipment for manual, semi-automated and automated assembly, testing and adjustment processes and are aware about the specific opportunities and limitations.

-

Description

1. Key performance indicators for production machines in the final assembly plant

- Tolerances and capability

- Availability

- Cycle time and volume

- Quality management

2. OOA method to work out modular concepts for production machines in the final assembly plant regarding an efficient production of the vehicle

3. Structure of modern final assembly plants

- Principles of planning assembly plants

- Structures of assembly systems, e.g. assembly lines

- Structures of End of Line test and adjustment systems

4. Principles of assembly stations regarding vehicle requirements

- Examples “rear axle assembly” and “marriage” stations

- Fixation technologies

- Virtual Commissioning

- Manual, semi-automatic and automatic processes

- Conveyors, manual and automatic handling devices and robotic

5. Principles of End of Line testing and adjustment stations regarding vehicle requirements

- Basics of linear algebra and vector calculation

- Wheel alignment

- Head lamp and driver assistance systems setting

- Roll-, brake-, ABS-testing

- Manual, semi-automatic and automatic processes and adjustment devices

- Optical sensor technologies

-

Assessment

Written exam (100%)Knowledge regarding the lessons.

-

Note

Literature resourcesLiterature, Patents and Norms

Mechern, 14.06.2024, Dr. T. Tentrup

-

Details

- Course title: Assessment of Finite Element Calculations

- Number of ECTS: 3

- Course code: MSPC-6

- Module(s): 1.2 MECHANICS

- Language: EN

- Mandatory: No

-

Objectives

On completion of the course unit successful students will be able to use and understand a well-established norm [1] for analytical strength assessment of components based on local stresses calculated with the help of the finite element method.

As this norm is well known in industry and research (6th edition), its use and the respective background are detailed in this lecture. The student understands why the norm imposes a specific procedure for static and a different one for fatigue assessment and what the relevant influence factors are. All important background information is given by two classical textbooks [2], [4], multiple handouts and three discussed examples. The additional information deploys the relevant physical background phenomena quantitatively, where the norm is short. Vice-versa, the textbooks etc. do not contain numerical quantity values for direct use, what the only norm does.

-

Course learning outcomes

When a finite element calculation has been performed and the stresses have been calculated they have to be assessed with respect to the imposed stress limits depending on the charging of the component:

Static assessment based on linear and non-linear Finite Element Method (FEM)

Fatigue assessment based on linear stress and strain calculations

-

Description

Lecture 1: Introduction to the problem (General survey of FKM, Chapt. 0, [1]) and by discussion of an analytical example: stress distribution in a thick walled pressurized tube. Repetition of principle stresses and three stress hypotheses for combined stress. Difference between Fatigue Assessment and Fracture Mechanics (1.handout 7 pages, fracture mechanics not part of this lecture), definition of local and nominal stresses (assessment by use of nominal stresses is not part of this lecture).

Lecture 2: Definition of local, uniaxial, multiaxial, proportional, synchronous and non-proportional stresses. Procedure of calculation and demarcation with respect to nominal stresses, repetition of basics: effect of notches, stress concentration factor SCF or Kt

Lecture 3: Chapt. 3.0 – 3.1.2.2 of FKM [1]: combined stress in case of brittle and ductile material, multiaxiality, repetition of basics: stress-strain curve, simplification of elastic-ideal plastic behavior, hardening, real stress and real strain, yield-curve of a component, (2.handout 1 page, reinforced concrete), section factor, stress and strain distribution of a smooth specimen subject to bending, NEUBER equation with example (3.handout 1 page), plastic strain limits vs. elongation at break, plastic limit loading.

Lecture 4: Chapt. 3.1.2.2 – 3.2.1.2 of FKM [1] : effect of thickness and repetition of basics: plain stress sate and plain strain state, full plasticity and collapse loading, effect of pre- or residual-stress for brittle and ductile material, loading and unloading, reverse-plastification, (4.handout 1 page, effect of post-weld-heat-treatment)

Lecture 5: Chapt. 3.2.1.2 – 3.6.1.2 of FKM [1]: effect of thickness, elevated temperature including creep (5. handout 2 pages), section factor npl of FKM based on NEUBER rule, plastic notch factor and strain limit, typical safety factors and assessment incl. multiaxiality; definition of stress categories: primary & secondary, membrane, bending & peak stresses only to demark from ASME-code approach (not part of the lecture), repetition of basics: failure load of brittle and ductile material, Charpy-impact testing.

Lecture 6: Chapt. 4.0 – 4.1.3.1 of FKM [1] : s-n-line, stress ratio R, stress spectrum, endurance limit, slope k, and repetition of basics: cyclic loading, proportional, synchronous and non-proportional loading, finite life and endurance limit, stress-range R and the s-n-line (Wöhlerline), ‘slope’ of the s-n-line, knee point, typical scatter Tn and Ts values, statistics of cyclic testing and normalized s-n-line

Lecture 7: Chapt. 4.1.3.1 – 4.1.3.2 of FKM [1] : constant amplitude s-n-curve, mean stress influence, and repetition of basics: alternating and pulsating loading, endurance strength limits for different materials and loadings, effect of mean stress- Haigh and Smith diagram, mean stress sensitivity, simplified Haigh diagram acc. to FKM, static limits of the Haigh-diagram, effect of surface, size, stress gradient (or volume) and corrosive environment on the endurance limit, effect of notches, definition of fatigue notch factor Kf vs. form factor Kt (=SCF), dynamic support factor= Kt – Kf-ratio

Lecture 8: Chapt. 4.1.3 – 4.6.2.2 of FKM [1]: influence of mean stress and variable amplitude, fatigue limit=endurance limit, temperature influence, 6. handout 1 pages to repeat support factor= Kt – Kf-ratio, related stress gradient, design factor KWK, mean stress factor KAK, variable amplitude fatigue strength factor KBK, the different fields of the HAIGH diagram, two simplified models of s-n-lines, Miner´s elementary and consistent rule, damage sum, degree of utilisation, stress spectrum and its determination by rainflow- and rainfill=reservoir-counting (example with 7. handout -5 pages )

Lecture 9: First full example, based on our open access-peer-reviewed publication [3] (8 . handout – 7 pages )

Lecture 10: Chapt. 6.0 – 6.2.2 of FKM [1]: Discussion of two fully detailed examples in the annexe of FKM

Lecture 11: ANSYS-Workbench, computer room: introduction into the software, modelling of a thick walled tube (Stephan Sellen)

Lecture 12: ANSYS-Workbench, computer room: 9 . handout, send by email – geometry of first example, ref. to lecture 9, (Stephan Sellen) )

Lecture 13: ANSYS-Workbench, computer room: full linear and non-linear calculation acc. to FKM for the example of lecture 9, repetition and summary of theory (10 . handout – 7 pages, (Stephan Sellen) )

Lecture 14: repetition and summary, Q+A, exam preparation

-

Assessment

Written exam (100%) -

Note

[1] FKM Guideline, 6th Edition 2012, Analytical Strength Assessment of Components, ISBN 978-3-8163-0649-8

Literature resources

[2] Fundamentals of Machine Elements, SI Version, 3rd Edition, CRC-Press, ISBN 978-1-4822-4748-0

[3] Design rules for autofrettage of an aluminum valve body; S. Sellen, S. Maas, T. Andreas, P. Plapper, A. Zürbes and D. Becker, http://onlinelibrary.wiley.com/doi/10.1111/ffe.12328/abstract

[4] Issler, Ruoss, Häfele, Festigkeitslehre – Grundlagen, Springer, ISBN 3-540-40705-7 10 handouts during the lectures (in English)

-

Details

- Course title: CAD & CAE

- Number of ECTS: 4

- Course code: MSPC-7

- Module(s): 1.2 MECHANICS

- Language: EN

- Mandatory: No

-

Objectives

The main objectives are:

1-Development of a professional knowledge in technical communication tools available in actual design offices. The focus will be on understanding the different methodology of numerical model creation, using full 3D parametric features capabilities.

2- Structural validation of parts and systems.

3- Comprehension and production of Engineering drawings for use in different Engineering specialisations.

-

Course learning outcomes

The students in the defined scope of the course can:

1- professionally work with a commonly used commercial CAD and FEA software

2- validate structurally simple parts, assemblies and mechanical concept

3- Generate parametric design of Products and Systems including sustainability constraints

4- Communicate technical concepts using industrial modern tools, and to understand the various standards and practices in the mechanical industrial field

-

Description

1- Introduction to CAD

2- Feature modelling / advanced sketch

3- Parametric Modelling

4- structural simulation

5- Validation of parts and systems

6- Optimisation of geometry and material

7 Overall capabilities of CAE software

-

Assessment

Final written exam -

Note

Inventor Professional Revit Documentation and Online help

Literature resources

MemoTech – Dessin Technique et norm CAO – C.Hazard

Precis de construction mecanique – R.Quatremer – Nathan

Guide du Dessinateur industriel – A.Chevalier – Hachette

Technisches Zeichnen – Hoischen – Edition Cornelsen / Girardet

“Fundamentals of Machine Elements, Third Edition: SI Version”, Steven R. Schmid, Bernard J. Hamrock, Bo. O. Jacobson.

“Fundamentals of Machine Components Design”, R. C. Juvinall, Kurt M. Marshek.

„Roloff/Matek Maschinenelemente“, Herbert Wittel, Dieter Muhs, Dieter Jannasch, Joachim.Voßiek.

“Engineering Drawing and Design”, 5th Edition, David A. Madsen, David P. Madsen

“Fundamentals of Machine Elements, Third Edition“, Steven R. Schmid, Bernard J. Hamrock, Bo. O. Jacobson ·

“Fundamentals of Machine Components Design “ , R. C. Juvinall, Kurt M. Marshek

“ Mark’s Calculations for Machine Design “ , Thomas Brown.

“ Shigley’s Mechanical Engineering Design“, Richard G Budynas, Keith J Nisbett.

-

Details

- Course title: Machine design

- Number of ECTS: 4

- Course code: MSPC-8

- Module(s): 1.2 MECHANICS

- Language: EN

- Mandatory: No

-

Objectives

The aims of the course are:

+ to deepen knowledge of designs of machine elements gained in the courses of machine elements in bachelor study

+ to present advanced design methods of mechanical parts

+ to introduce advanced tools (CAE) for analyses of machine design: FEA – ANSYS/ Inventor, CAD – Inventor, reporting/ calculations – Mathcad, and Fusion 360 – CAD cloud computing

+ to build base student knowledge of machine design, which is needed for their projects in semester 2 – Machine Design Exercise.

-

Course learning outcomes

After the course, the student:

+ is able to carry out a design process for mechanical objects

+ uses in practice analytical equations of mechanics to design machine elements

+ solves real technical problems using previously acquired knowledge of subjects: mechanics, strength of materials, machine element design, and CAD

+ is able to propose an appropriate technological process of manufacture and assembly for a particular machine element

+ knows how to utilize CAE tools like ANSYS, Inventor, and Mathcad in design projects

+ is able to understand the concept of machine element optimization and employ this method in projects.

-

Description

Part I Fundamentals

+ Tolerances and fits. Deviations of form and position and surface roughness

+ Loads, analysis, materials, static body stresses

+ Fatigue and impact

+ Safety factor, reliabilityPart II — Machine Elements

+ Stresses and deformations in cylinders

+ Shafts and associated parts

+Bearings

+ General gear theory

+ Spur sears, helical, bevel and worm gears

+ Manual gearboxes designs

+ Brakes and clutches

+ Flexible machine elements

+ Belts, wire ropes, rolling chains

+ Machine element optimization -

Assessment

Written exam (100%)The written exam consists of 3 problems to solve; each problem will be assessed, taking into account a used methodology – 60%, and numerical correctness of the solution – 40%.

-

Note

“Fundamentals of Machine Elements, Third Edition“, Steven R. Schmid, Bernard J. Hamrock, Bo. O. Jacobson

Literature resources

Course materials available on Moodle system

Supplementary:

“Fundamentals of Machine Components Design“, R. C. Juvinall, Kurt M. Marshek

“Mark’s Calculations for Machine Design“, Thomas Brown.

“Shigley’s Mechanical Engineering Design“, Richard G Budynas, Keith J Nisbett.

“Engineering Drawing and Design“, 5th Edition, David A. Madsen, David P. Madsen

-

Details

- Course title: Fundamentals of Network Theory

- Number of ECTS: 3

- Course code: MICS2-7

- Module(s): 1.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

Split into two parts, part (A) will introduce fundamental aspects of generic mathematical networks (graphs), usually summarized as network science, and not limited to computer networking, but also applicable to networks in social media, machine learning (artificial neural networks), road traffic and vehicle communication, cryptocurrency transactions, energy transport, biology, citation networks and many more.

Part (B) will explain model fundamentals of quantum networking, from basic qubit notations, Bell states, entanglements, 2-qubit gates, until quantum repeaters using entanglement swapping for multi-hop quantum communication networks.

-

Course learning outcomes

At the end of the course, students will be able to identify and apply suitable models and graph representations with related graph metrics to analyse practical networked scenarios, and reason about most efficient application of (network centrality) metrics. Students will understand power and limits of end-to-end concepts of quantum networking applied to distributed communication scenarios including entanglement swapping.

-

Description

Part (A): Eigenvectors and eigenvalues, adjacency matrix, hypergraphs and bipartite networks, trees and planar networks, degrees, paths and components, graph Laplacian.

Part (B): Introduction to quantum networking, scalar product, unitary matrices, Hadamard transformation, 2-qubits, entanglements, manipulation of qubits, introduction to gates, example 2-qubit gates (CNOT, Pauly, swap), no-cloning theorem, Bell states and Bell measurements, quantum repeater and entanglement swapping, fundamental experiments like Mach-Zehnder interferometer.

-

Assessment

Combined (continuous and end-of-course) assessment

Several take-home assignments (“exercises”) will be issued and submitted by the students within 2 weeks deadlines.

Each assignment will be discussed in plenum and will be followed by small online tests which will be marked.

Assessment: Final written exam (60%), online tests (20%), exercises submission and discussion (20%)

-

Note

Slides, comprehensive lecture notes, exercise assignments. Additional references provided during the course. All information will be made available on Moodle’s course page.

-

Details

- Course title: Networking

- Number of ECTS: 3

- Course code: MICS2-8

- Module(s): 1.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

Introduce higher networking layers and mathematical descriptions of network concepts as Multiple Access Control (ALOHA, collision detection and resolution), Error detecting and correcting codes, ARQ, routing and flow control, Queueing and QoS.

-

Course learning outcomes

Describe fundamental parameters of networks and medium access control,- Take optimal stochastic decisions based on observations, – Differentiate existing communication topologies according to their performance, security and robustness, – Apply theoretical concepts to real world communication architectures for performance or security optimisation -

Description

Point-to-Point Data Transmission: synchronous multiplexing (TDM, FDM, CDM, S+TDM), asynchronous multiplexing (frame synchronization, frame length optimization, pipelining effect).

Error Detection and Correction: basic definitions, error probabilities, binary symmetric channels, information entropy, throughput and packet error rates of ARQ protocols (stop-and-wait, go-back-N, selective repeat), correction and decoding (maximum likelihood, minimum distance, CRC).

Random processes and probability distributions of discrete and continuous experiments (Binomial-, Poisson-, distance-, Erlang-i-distributions and transitions between them), introduction to Markov processes.

Introduction to Mathematics of Networks (“Network Science”): adjacency matrix, weighted networks, cocitation and bibliographic coupling, acyclic directed networks, hypergraphs and bipartite networks, degrees, paths, Eulerian and Hamiltonian paths, graph Laplacian.

Multiple Access Control: ALOHA, Slotted ALOHA, distributions for infinite and small number of senders, quantifying success drift, stabilization methods (binary exponential backoff, pseudo Bayes), collision resolution methods (tree and first-come-first-serve), throughput of CSMA, collision avoidance.

Introduction to Queueing: models, Little’s theorem, examples with M/M/1, M/M/1/n, M/G/1

If time allows (otherwise this will be continued in course MICS2-23: “QoS in Computer Networks”): introduction to preemptive and non-preemptive priorities (M/M/m), Jackson networks, anonymity protocols and QoS in distributed systems. Learning outcomes – Describe fundamental parameters of networks and medium

-

Assessment

Continuous assignment

Several take-home assignments will be issued and submitted by the students within 2 weeks deadlines. Each assignment will be discussed in plenum and will be followed by small online tests which will be marked.

-

Note

Slides, lecture notes, exercise assignments. Additional references provided during the course.

-

Details

- Course title: Sensors & signal processing

- Number of ECTS: 3

- Course code: MSPC-9

- Module(s): 1.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

Understand the basic metrology, sensor concepts and signal processing methods in the context of engineering.

-

Course learning outcomes

Gain a basic understanding of sensor and signal processing concepts. -

Description

Basic SI units, electrical circuits, linear time-invariant systems, Fourier analysis, analog and digital sensor data acquisition, introduction to fundamental sensor types. -

Assessment

Written exam (100%)- Objectives: Test the knowledge, skills, and aptitude acquired by the students.

Assessment rules: test of various types of questions, 2-hour duration.

Assessment criteria: The mathematical approach, presentation, and the final answer.

-

Note

Lecture slides

Literature resources

Own written notes from lectures

Optional:

Jacob Fraden, Handbook of Modern Sensors: Physics, Designs, and Applications, Springer 2010, ISBN: 978-1441964656

-

Details

- Course title: Technical Energy Systems Modeling and Simulation

- Number of ECTS: 4

- Course code: MSPC-10

- Module(s): 1.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

Knowledge of how to model and simulate dynamic system.* Build mathematical models for dynamics of technical systems derived from basic principles * Use advanced tools for numeric and symbolic computing * Apply decomposition, transformation and approximation methods * Elaborate a case study and present computational results.

-

Course learning outcomes

Learning how to apply simulation methods on given practical problems, having different types of technical dynamic (energy) systems. In the seminar, techniques for modeling of technical systems are elaborated in case studies for typical technical systems employing symbolic and numeric computation methods. -

Description

Theoretical basis lecture, hands on workshops with Matlab.1 Technical Systems2 System Structures and Model Descriptions3 Continuous Models from Variational Analysis4 Model Simplification5 Optimal System Operation. -

Assessment

Take-home assignment (30%)- Seminar simulation work.

- Assessments will be given on weekly bases in first 6 week, after that self-study and autonomous working on single or group projects.

Oral exam (70%) -

Note

Literature resourcesKondipudi, Prigogine : Modern Thermodynamics, WileySon, 1998

Baumann : Symmetry Analysis of Differential Equations, Springer Verlag, 2000

Ljung, Glad : Modelling of Technical Systems, Prentice Hall, 1995

Wellsted: Introduction to Physical Modeling, Control Systems Principles, 2000

Course offer for Semestre 2 (2025-2026 Summer)

-

Details

- Course title: Manufacturing systems

- Number of ECTS: 3

- Course code: MSPC-12

- Module(s): 2.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Being familiar with different traditional and advanced manufacturing technologies with the emphasis on the ones available in the region, to prepare the students for a professional industrial role.

-

Course learning outcomes

You can prepare a professional presentation for academic areas or industry. -

Description

- Overview of different manufacturing technologies, their corresponding advantages, limitations, and requirements.

- Primary shaping: casting, additive manufacturing, powder metallurgy, galvanoplasty, semisolid processing.

- Materials forming, cutting, and joining.

- Coating and changing materials properties via heat treatment.

- Ferrous and non-ferrous alloys.

- Primary shaping of plastics.

- Manufacturing technologies in automotive glass industry.

- Presentation skills and professional reporting.

-

Assessment

Written exam (10 points)

Objectives- You assess which manufacturing technique is suitable for a required design, application or properties.

- You can list the main applications of each manufacturing technique.

- You can list the advantages and limitations of a given manufacturing techniques for a defined part.

- You can prepare and deliver a professional presentation and reporting for academic and industrial environments.

Assessment rulesMultiple-choice questions, short-answer questions, analytical questions

Presentation (7 points)

ObjectivesYou can prepare a professional presentation for academic areas or industry.

Assessment criteriaMastery on the topic, technical quality, visual quality and comprehensiveness of the presentation, soft skills in presentation, timing, referencing

Take-home assignment (3 points)

ObjectivesYou can prepare a professional presentation for academic areas or industry.

Assessment criteriaTechnical quality and comprehensiveness, referencing

-

Details

- Course title: Product Planning & Marketing for Engineers

- Number of ECTS: 3

- Course code: MSPC-11

- Module(s): 2.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

The objective of the course is to enable engineering students to integrate a market-oriented perspective into their thinking, (product-) designing, and decision-making.

-

Course learning outcomes

After successfully completing this module, students will be able:

– to evaluate (new) products and service offers in terms of customer value and potential market positioning;

– to apply relevant marketing strategies to a given company and/or business unit;

– to analyse determinants of buying behaviour and transfer this knowledge into applicable market segment strategies;

– to integrate the customer perspective into the product development process;

– to evaluate basic pricing and communication strategies in line with product positioning. -

Description

- Basic concepts of marketing

- Marketing strategies

- Determinants of Buying Behavior

- Market Segmentation

- Product/Brand Strategies

- Product development and positioning

- Pricing- and Communication Strategies

-

Assessment

Written or oral exam (70%)

Active participation (10%)

Case study solution (20%) -

Note

Literature resources

- Homburg, Ch., Küster, S., Krohmer, H. (latest edition): Marketing Management: A Contemporary Perspective, McGraw Hill

- Kotler, P., Armstrong, G. (latest ed.): Principles of Marketing, Prentice Hall

-

Details

- Course title: Programming for Engineers II

- Number of ECTS: 4

- Course code: MSPC-14

- Module(s): 2.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

The aim of the course is to teach basics of programming with modern languages (Python), software engineering fundamentals and practical applications of data analytics and visualization for engineers. The students can practically apply what they have learned in assignments and student projects along their student program or their careers.

The course consists of the following learning units:

· Introduction to programming

· Concepts of programming such as object-oriented programming

· Principles of software development and UML

· Introduction to fundamental python packages used in engineering.

· Introduction to data analytics, machine learning and data visualization.

-

Course learning outcomes

Having successfully completed the module, students will be able to demonstrate knowledge and understanding of:

· Programming algorithms for solving tasks in engineering.

· Using modern tools and methods for software development.

· Being able to process different data sets and analyze them.

· Utilize visualization methods on large data records.

· Identify the required computational tools for solving a particular engineering task. -

Description

1. Introduction to computation and programming languages (week 1)

2. Elements of python programming language such as statements, operators, loops, variables, simple types, complex types (week 2 and 3)

3. Concepts of object-oriented programming, i.e. classes, objects, methods, polymorphism (week 4 and 5)

4. Basics of software design (week 6 )

5. Data structures and data visualization (week 7 and 8)

6. Introduction to machine learning and AI tools (week 9 and 10)

7. Systems design, APIs and applications (week 11)

-

Assessment

Mid-term exam (25%)On-site exam that will evaluate the acquired knowledge and aptitudes of the student considering the first half of the course. It is composed of a written section (e.g., multiple-choice and open question) and a coding section.

Homework (25%)Series of assignments that will help to reinforce the knowledge acquired during classes. They are programming tasks that evaluate the capacity of the student to extrapolate class knowledge to different situations.

Class participation (10%)Considers active participation of the students and their capacity to integrate themselves into class discussions. This assessment task can also consider the participation of students in forums or any platform where discussion is expected. The grade is determined by Lecturer.

Final exam (40%)On-site exam that will evaluate the acquired knowledge and aptitudes of the student considering the whole course. It is composed of a written section (e.g., multiple-choice and open question) and a coding section.

-

Details

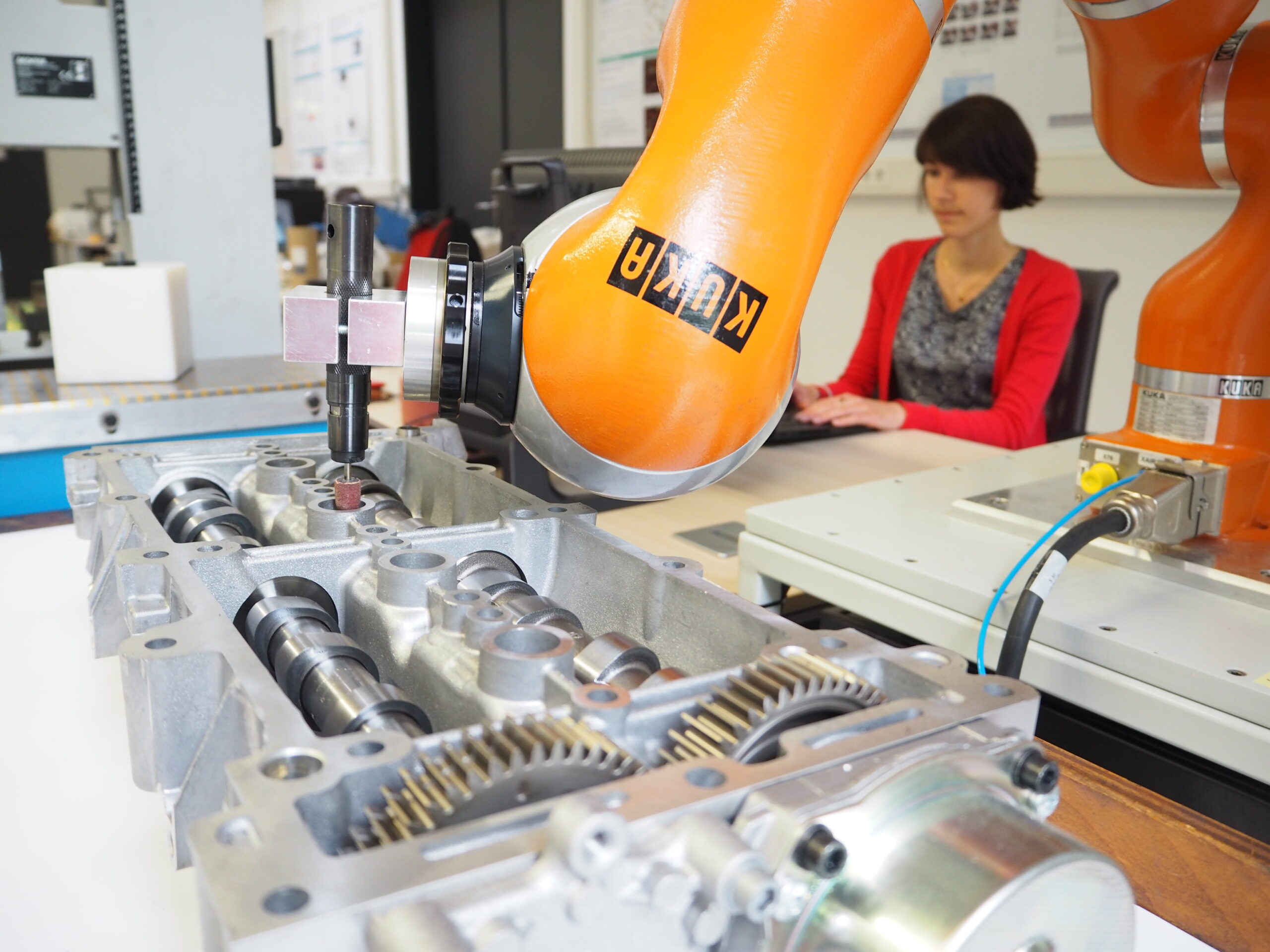

- Course title: Robotics

- Number of ECTS: 4

- Course code: MSPC-13

- Module(s): 2.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Details

- Course title: Additive Manufacturing Technology

- Number of ECTS: 3

- Course code: MSPC-16

- Module(s): 2.2 MECHANICS

- Language: EN

- Mandatory: Yes

-

Objectives

Develop a comprehensive understanding of AM technologies.

-

Course learning outcomes

Identify and select appropriate AM technologies for particular applications as well as learn how to 3D print. -

Description

The course provides an introduction to Additive Manufacturing (AM) or 3D printing technologies, covering the background, actual methods, available printable materials and also current and future applications. AM’s global impact and the key players in AM industry will be briefly laid out. The course will consist of lectures and hands-on laboratory sessions, where students will generate 3D designs and print.

-

Assessment

Continuous assessment

In-class Assignments (25%): Students will complete regular assignments to demonstrate their understanding of the material.

Group Projects (75%): Collaborative group tasks will be part of the course, including a presentation as a component of the assessment.

-

Details

- Course title: Advanced Control

- Number of ECTS: 3

- Course code: MSPC-19

- Module(s): 2.2 MECHANICS

- Language: EN

- Mandatory: Yes

-

Objectives

In the creation of sustainable products, control engineering plays a more and more important role. In order to realize increasingly complex functionalities and so called “smart” products, control systems with advanced information processing capabilities have to be embedded in the product.

As an introduction, methods to model technical products and processes as sets of linear or nonlinear differential equations forming transfer function models are considered. Based on this, basic and more advanced methods to develop control systems are derived and discussed using engineering examples. Furthermore, an introduction to system-identification methods and a digital control design will be given.

Finally, it will be discussed how basic and advanced control approaches could be simulated and tested using MATLAB software.

-

Course learning outcomes

1. The students should have a profound knowledge how to model technical products and processes as continuous, discrete-event or hybrid dynamic systems.

2. Draws bode diagram for any system and design a compensate controllers (lead, lag) via frequency response using MATLAB.

3. The students are able to design, implement and test basic and more advanced control systems based on the derived system-identification models.

-

Description

1. Introduction to dynamic system modelling

- basic principles

- transfer function model

- stability, transient response, and steady state error.

2. Basic linear control systems

- short repetition of basic linear SISO control

- bode diagram and frequency response analysis

3. Advanced linear control systems

- feedback control system design via frequency response.

- digital control system design

4. Introduction to system identification

- system identification theory

- data-driven control design.

5. Simulation, Testing and Implementation of Control Systems

- simulation and testing of dynamic and closed loop feedback systems using MATLAB software.

-

Assessment

Written examination (80%)A written exam, including different exercises, will be done at the end of all lectures.

2 assignments will be given before the final exam (20%)Take-home assignments with fixed deadlines will be given to the students to test their understanding of the lectures and to estimate their analysis capacities and how far they can look for additional information not provided in the lecture

-

Note

1.Nise, Norman S. Control Systems Engineering. John Wiley Sons, Sixth Edition,

2.Richard C. Dorf, and Robert H. Bishop (2008). Modern Control Systems, Eleventh Edition, Prentice-Hall, Inc.

3.Arun K. Tangirala. Principles of System Identification Theory and Practice. (Chapter: 1-3; 12-15)

4.Lennart Ljung, System Identification: Theory for the User. Second edition.

-

Details

- Course title: Advanced engineering materials

- Number of ECTS: 4

- Course code: MSPC-17

- Module(s): 2.2 MECHANICS

- Language: EN

- Mandatory: Yes

-

Objectives

Knowledge of structural materials (metals as ferrous and nonferrous alloys; ceramics and glasses;polymers, and composites) and their use in the view of a sustainable use of resources.

-

Course learning outcomes

The students will be capable to understand the different properties of the different key engineering materials and their use. -

Description

Crystallography

Diffusion

Phase Diagrams

Metals:

- Ferrous alloys (carbon and low-alloy steels, high-alloy steels, cast irons)

- Nonferrous alloys (aluminium alloys, magnesium alloys and other alloys)

- Processing of metals and the influence on their properties

- Glasses

- Processing of ceramics and glasses and the influence on their properties

Polymers:

- Thermoplastic polymers

- Thermosetting polymers

- Processing of polymers

Powder Metallurgy:

- Cemented Carbide

- Cermets

- Compaction

- Sintering

Mechanical and Physical Properties

Materials and our environment:- Environmental aspects of design

- Recycling

-

Assessment

Written Exam 1: Intermediate exam for 25% of the total grade

Written exam 2: Final exam for 75% of the total grade

-

Note

Literature resourcesMaterials selection in Mechanical Design, M. F. Ashby, Butterworth-Heinemann, Burlington, 3rd ed., 2006

Engineering Materials 1 2, M. F. Ashby, D. R. H. Jones, 3rd ed., Butterworth-Heinemann, Burlington, 2005.

Materials Science for Engineers, J. F. Shackelford, 6th ed., Prentice Hall New Jersey, 2005.

The Science and Engineering of Materials, D. R. Askeland, 3rd ed.,Nelson Thormes Ltd., 1998.

Werkstofftechnik 1 und 2, W. Bergmann, 4. Auflage, Hanser-Verlag München, 2002.

Werkstoffe, E. Hornbogen, 7. Auflage, Springer-Verlag Berlin, 2002.

Moderne Werkstoffe, R. Gadow, A. Killinger, Expert-Verlag, 2000.

-

Details

- Course title: Laser Technology for Manufacturing

- Number of ECTS: 4

- Course code: MSPC-15

- Module(s): 2.2 MECHANICS

- Language: EN

- Mandatory: Yes

-

Objectives

To familiarize the students with lasers and their application in industry for their future career as the application of different lasers grow fast. Moreover, in case they want to continue their education or would like to follow their case study or thesis in a relevant field, they have enough scientific background.

-

Course learning outcomes

You assess which laser types are suitable for which applications.

You can implement concepts for new laser applications.

You can list the main types of lasers.

You can explain the basic terms of laser physics.

You can assess the potential of laser radiation based on the process parameters.

You can describe areas of industrial application of lasers -

Description

Introduction, basics of laser, definition, laser market, laser parameters

Basic properties of laser light, light propagation, beam caustics

Laser types (gas lasers, ion lasers, solid-state lasers, fiber lasers, diodes, VCSEL)

Light and interaction with matter (absorption, impact of material, temperature)

Beam conduction in fibers and transmissive optics, remote laser delivery

Laser safety

Applications of industrial machines and prototypes of hybrid laser machines

Process technology: Laser hardening, laser welding, laser brazing

Latest research results related to polishing, and welding of dissimilar materials -

Assessment

Written examThe written exam will count for 100% of the final grade.

A short preliminary exam (Quiz) will be organized and assessed during the semester. The result of this quiz, along with the active participation, will be also considered for the final grade (only if in favor of the student).

-

Details

- Course title: Machine Design Exercise

- Number of ECTS: 3

- Course code: MSPC-18

- Module(s): 2.2 MECHANICS

- Language: EN

- Mandatory: Yes

-

Objectives

The goal of this course is to develop the skills of students to design machine elements using gained knowledge from completed courses (Machine Design, CAD, FEA and others) and to employ this knowledge effectively in a real design project. The course focuses on engineering analyses: analytical calculations of the strength of materials, FEA calculations, 3D design tools and finally, good project reporting.

-

Course learning outcomes

Upon completion of the course, the student:

+ is able to work in a group and knows his place and task. They can communicate with other members and a project supervisor and accept responsibility.

+ they can use methods of project management.

+ can carry out a technical object’s design process and meet deadlines.

+ uses in practice computer-aided tools like ANSYS, Autodesk Inventor and Fusion 360.

+ solves real technical problems using previously acquired knowledge of subjects: mechanics, the strength of materials, machine element design, CAD.

+ is able to propose an appropriate technological process of manufacture and assembly. -

Description

The project topic is the design and analysis of a small mechanical assembly like a clutch, a torque limiter or a gear train.

The steps of the project are shown below:

+ Creative formulating and discovering technical problems.

+ Finding solutions and analyses of issues.

+ A selection of an optimum concept and its innovation.

+ An accomplishment of strength calculations and technical documentation using computer-aided systems.

+ Consideration of manufacturability design aspects.

+ Verification of an adopted design solution to reach the prototype stage.

+ Create a final report of the project ready for a public presentation. -

Assessment

Take-home assignment (100%)The completed project will be evaluated by taking into account: the quality of the report, the correctness of strength calculations, self-reliance during the project, proactivity, and how to solve engineering problems in the project.

No retake evaluation can be done in winter semester / any project failed must be retaken on the following summer semester (on the following academic year). -

Note

“Fundamentals of Machine Elements, Third Edition”, Steven R. Schmid, Bernard J. Hamrock, Bo. O. Jacobson

Literature resources

Course materials available on Moodle

Inventor Nastran, Autodesk manuals

ANSYS Workbench training materials

ANSYS manuals

Supplementary:

“Fundamentals of Machine Components Design”, R. C. Juvinall, Kurt M. Marshek

“Mark’s Calculations for Machine Design”, Thomas Brown.

“Shigley’s Mechanical Engineering Design”, Richard G Budynas, Keith J Nisbett.

“Engineering Drawing and Design”, 5th Edition, David A. Madsen, David P. Madsen

-

Details

- Course title: Networked Feedback Systems

- Number of ECTS: 5

- Course code: MSPC-20

- Module(s): 2.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: Yes

-

Objectives

The objective of this course is to introduce students to networked feedback structures in interconnected information and communication technology in technical environments.

-

Course learning outcomes

* Identify feedback structures, decompose them and formulate continuous and sequential dynamics

* Determine reliable discrete or continuous enclosures for structure-variations and uncertainties

* Design controls with guaranteed dynamic tolerances

* Design reliable automata in technical context.

-

Description

Networked feedback and feedforward- sampling, scheduling and communication- continuous system representations- dynamics and approximations- systems over the binary field- binary transfer function and stability- combined systems and decompositions- feedback design in multiloop structures. -

Assessment

The grade for the course compiles 30% classwork (assignments and taking part in the lecture, attendance) and 70% exam (paper/report + presentation).

-

Details

- Course title: Information Theory and Coding

- Number of ECTS: 5

- Course code: MICS2-20

- Module(s): 2.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

The objective of this course is to provide an understanding of fundamental communication limits and means of approaching them

-

Course learning outcomes

* Compute fundamental communication limits

* Compress simple information sources

* Describe the fundamental blocks of digital communication systems (physical layer)

* Encode binary information with a convolutional code

-

Description

The course contains:

– Shannon’s concept of mathematically quantising information and uncertainty for a communication setup

– Explanations that both compression and error free transmission have an extremal rate which can be computed via entropy and mutual information

– Methods to compress sources

– Digital transmission techniques and their complexity for inter-symbol-interference channels

– Simple error correction codes, convolutional codes -

Assessment

Final Exam: 75%

Homework: 25%

-

Details

- Course title: Quality of Service in Computer Networks

- Number of ECTS: 5

- Course code: MICS2-23

- Module(s): 2.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

The objective of this course is to introduce quantitative measures for network performance (like throughput, error correction, delays, routing) for different network topologies to

be applied to security protocols. It also sensibilises for differences between static and dynamic networks as well as centralised and de-centralised topologies concerning reliability and trust issues -

Course learning outcomes

* Describe performance metrics and list parameters of dedicated networks and protocols.

* Name and reproduce definitions of relevant parameters that theoretically characterise the communication traffic incl. queues, routing and error probabilities

* Analyze existing solutions according to their capabilities for throughput, error rate and security

* Construct and adapt real world communication architectures and protocols with given Quality of Service requirements on the basis of the theoretical concepts

-

Description

1. Intro

2. Recap: Random Processes

3. Recap: Homogeneous Markov Chains

4. Commutation Systems: Components and modules

5. Communication Traffic as Random Process

6. Routing and Flow Control

7. Introduction to Queueing Theory

8. QoS in TCP/IP -

Assessment

70% Final Exam

30% Successful preparation, submission and active participation in exercise sessions

Course offer for Semestre 3 (2025-2026 Winter)

-

Details

- Course title: Advanced Project / Case Study

- Number of ECTS: 12

- Course code: MSP-30

- Module(s): 3.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Purpose of the case study in the third master semester is to apply your engineering learnings but even more relevant to learn scientific work, and thus to prepare your Master project.

-

Description

To ensure the desired broad learning, we require that the case study and the Master thesis are distinct, thus you shall work on two different projects with two different supervisors. -

Assessment

Written report + 15 mins. presentation.+ 5 mins QA

-

Note

BE CAREFUL: In order to ensure broad education, we require Advanced Project / Case Study Master Thesis being supervised by different Professors.

-

Details

- Course title: Design for Circularity

- Number of ECTS: 2

- Course code: MSP-66

- Module(s): 3.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Comply with circular economy obligations understand End-of-Life needs.

-

Course learning outcomes

Data collection of end-of-life process circular product designs adapted to it.

-

Description

Theoretical background & practical group application.

Visit:

The aim is to give the students a first impression of possible design shortcomings that make it more difficult to repair or that are responsible for a faster need for repair. The visit is also part of the data collection for their group work, which they have to present at the end of the semester.

Lectures:

In the 4 lectures, students are taught the necessary theoretical background to the circular economy. The aim is to give them a clear understanding of the future requirements of engineering tasks (opportunities for future jobs) and the requirements from a regulatory perspective. The first lecture will give an introduction to the circular economy. The second lecture will focus on the end-of-life processes to give students an insight into how different products are sorted, recycled or dismantled. The third lecture deals with the beginning of life, i.e. the design and the newly required product passports. The fourth and final session will focus on best practices currently used in the industry.

Workshops:In the two workshops, the theoretical knowledge gained from the lectures will be applied in practice. During the two-day block course, Lecture 2 and Lecture 3 are always followed by a practical workshop. The first workshop focuses on the data collection of end-of-life processes, where the students have to analyze an industrial recycling process. The second block course focuses on the design part, where students fill out a Product Circularity Data Sheet (PCDS) and rethink the product designs that go through the previously analyzed recycling process.Feedback & Discussion sessions:

During the three feedback sessions, the groups need to present the advancement of their works to all the others. The first session will before the discussion with experts from CELL and RepairCafé, in order to prepare for the expert session. The second feedback session is together with experts from CELL as well as RepairCafé. The final feedback session is before the pitching sessions, where the students will get support from an expert of the incubator about how to prepare their final pitch.

Group Works:In the first lecture, the students are divided into different groups of 3 to 4 people and have to decide on a specific product category (e.g. electronic devices, clothing, …). During the semester, the different groups have to collect information about the whole life cycle of the product group and develop new design features that increase the circularity of the product. There are several tasks to fulfill: First, they have to collect data on the end-of-life processes of the product group, which includes the RepairCafé in Walferdange. Then they have to analyze different life cycle possibilities of the product group before developing design features to improve circularity. Finally, they have to find a way to share their knowledge with potential customers. The results of the group work are presented in the final pitching session as well as in a small report of maximum 10 pages.

-

Assessment

Assessment tasks

Type of assessment

Grading scheme

Weight for final grade

Task 1

Attendance

Pass/Fail

20%

Objectives

Interactive course, so attendance is mandatory important

Assessment rules

At least 80% presence need to be reached

Assessment criteria

If not at least 80% is reached, no points will be given

Task 2

Presentation

20 points (0-20)

50%

Objectives

Final group presentation in the form of a pitch

Assessment rules

Presentation should be maximum of 20 minutes

Assessment criteria

Based on presentation clarity results

Task 3

Take-home assignment

20 points (0-20)

30%

Objectives

Next to presentation, final report will be graded as well

Assessment rules

Clearly structured report maximum of 10 pages

Assessment criteria

Quality of the report

-

Note

Literature:

1)Ellen MacArthur Foundation:

-https://www.ellenmacarthurfoundation.org

2)RepairCafe:

-https://www.repaircafe.lu/

-https://www.repairmonitor.org/

3)PCDS:

-https://terramatters.net/fr/a-propos

4)Scientific Papers:

-https://www.mdpi.com/2313-4321/8/6/89

-https://www.sciencedirect.com/science/article/pii/S0959652622048612

5)Legislation:

– https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en

– https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainable-products-regulation_en

– https://environment.ec.europa.eu/topics/circular-economy/green-claims_en

– https://environment.ec.europa.eu/topics/waste-and-recycling/packaging-waste_en

– https://www.iso.org/committee/7203984.html

-

Details

- Course title: Integrated management systems

- Number of ECTS: 3

- Course code: MSP-57

- Module(s): 3.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

Learn contents of management systems and to act as an auditee in (certif.) audits.

-

Course learning outcomes

Can act as an auditee in (certif.) audits; knows, what it is all about IMS in meetings.

-

Description

Chapters of management system standards, processes and procedures, background.

-

Assessment

Written exam – 100% -

Note

-Quality Management e-learning Deutsch/English, WEKA-Verlag

Literature resources

-Tilo Pfeifer / Robert Schmitt (Hrsg): Masing Handbuch Qualitätsmanagement, Hanser-Verlag, 16. Ausgabe 2021

-Tilo Pfeifer: Production Metrology, De Gruyter 2002

-The EFQM Model 2020, www.EFQM.org , free Download

-

Details

- Course title: Scientific writing and presentation skills

- Number of ECTS: 3

- Course code: MSP-61

- Module(s): 3.1 COMMON CORE

- Language: EN

- Mandatory: Yes

-

Objectives

This course aims to give students the background and confidence to write effective scientific reports.

The students will learn the fundamentals of effective scientific and professional writing. Presentation skills, verbal and non-verbal communication as well as specific documents such as the executive summaries will be covered.

-

Course learning outcomes

At the end of the course the student should be able to express ideas in a clear, coherent and concise written form, gain control over nonverbal language during an oral presentation and interact with the audience.

-

Description

Presentation skills. Scientific writing skills.

-

Assessment

Task 1: take-home assignement (33.3%)- Objective: Deliver all assignments or homeworks

- Criteria: Apply the rules for concise, coherent and positive writing

Task 2: take-home assignement (33.3%)- Objective: Perform a 7 minute oral presentation

- Criteria: Apply the rules for eye contact, intonation, presentation layout and body language

- Assessment rules: The text will be graded according to the criteria defined in the sessions

Task 3: take-home assignement (33.3%)- Objective: Write a report

- Criteria: Apply the rules for coherence, clarity and technical content

- Assessment rules: The text will be graded according to the criteria defined in the sessions

Mandatory attendance -

Note

Literature and resourcesAll literature and resources are given during the sessions in form of a script.

-

Details

- Course title: Mandatory 10 weeks industrial internship

- Number of ECTS: 0

- Course code: MSP-64

- Module(s): 3.1 COMMON CORE

- Language:

- Mandatory: Yes

-

Details

- Course title: Sensors & signal processing [old]

- Number of ECTS: 3

- Course code: MSP-46

- Module(s): 3.2 MECHANICS

- Language: EN

- Mandatory: No

-

Objectives

Understand the basic metrology, sensor concepts and signal processing methods in the context of engineering.

-

Course learning outcomes

Gain a basic understanding of sensor and signal processing concepts.

-

Description

Basic SI units, electrical circuits, linear time-invariant systems, Fourier analysis, analog and digital sensor data acquisition, introduction to fundamental sensor types. -

Assessment

Task 1 – Active participation 10%

Objectives: Encouraging students in class activities to improve their thinking skills and introduce new concepts to their peers.

Assessment criteria: Student performance and participation in the classroom

Task 2 – Take-home assignment 40%

Objectives: Examination of students’ skills and understanding of the material taught in class.

Assessment rules: The assignments must be completed and submitted by the deadline.

Assessment criteria: The evaluation depends on understanding of the subject and the concept, the final results, mathematical approach, etc.

Task 3 – Written exam 50%

Objectives: Test the knowledge, skills, and aptitude acquired by the students.

Assessment rules: In-class test of various types of questions, 1.5-hour duration.

Assessment criteria: The mathematical approach, presentation and the final answer.

-

Note

Optional:

Literature list

Jacob Fraden, Handbook of Modern Sensors: Physics, Designs, and

Applications, Springer 2010, ISBN: 978-1441964656

-

Details

- Course title: Electrical Energy Production Transportation and Distribution

- Number of ECTS: 3

- Course code: MSP-44

- Module(s): 3.2 MECHANICS

- Language: EN

- Mandatory: No

-

Objectives

1. Knowing the different sources of energy contributing to the production of the electrical energy

2. Knowing the different solutions to network the power units together and with the consumer

3. Knowing the electrical and the mechanical conversion possibilities for the distribution of the electrical energy

4. Understanding the electrical power flow management between the power units together as well as with the consumer

5. Knowing the electrical power quality norms

6. Knowing the power losses generation and its relative cost in the energy systems for a sustainable

and rational use of the electrical energy

-

Course learning outcomes

The student will acquire a global knowledge about the production, transportation, distribution and conversion of the electrical energy, as well as its transformation into/from the mechanical energy.

The sustainable rational use of the electrical energy as well as the electrical energy management, are also covered.

-

Description

1. Production of the electrical energy

The energy sources (fossil fuels, nuclear, renewable)

The generation of the electrical energy2. Transportation of the electrical energy

Electrical power transmission

Power quality norms

Low to high DC and AC voltage grids

Coupling of voltage supplies3. Conversion and distribution of the electrical energy

Modern distribution systems

Transformation of the electrical energy4. Sustainable and rational use of the electrical energy

Power losses

Costs of the energy systems -

Assessment

Written exam (100%)

Objectives:1.To be able to define the fundamental electrical devices used for the production, transformation, transport and distribution of electrical energy

2.To be able to explain the operation of the electrical devices

3.To be able to calculate relevant values of electrical circuits made of passive components

Assessment rules:

Based on application exercises (theory, formal calculation simulation) and their correction during the lecture, the student must be able to answer questions and solve similar problems on his/her own.

Assessment criteria:

Quality of the answers consisting in a correct communication language (English), the detailed methodology and the calculation results. -

Note

Available at the University library or on internet:

[1] http://en.wikipedia.org/wiki/Electric_power

[2] James Northcote-Green, Robert Wilson, “Control and Automation of Electrical Power Distribution

Systems”, Taylor Francis 2007, ISBN 0-8247-2631-6

[3] Peter Zacharias, “Use of Electronic-Based Power Conversion for Distributed and Renewable

Energy Sources”, ISET 2008

[4] Adolf J. Schwab, “Elektroenergiesysteme – Erzeugung, Transport, Übertragung und Verteilung

elektrischer Energie“, Springer 2008, ISBN 3-540-29664-6

[5] H.J. Haubrich, G. Henneberger, H.C. Skudelny, Müller-Hellmann, “Elektrische Energie aus

regenerativen Quellen“, Vorlesung der RWTH Aachen 1994

[6] Andreas Wagner, “Photovoltaik Engineering – Handbuch für Planung, Entwicklung und

Anwendung“, Springer 2006, ISBN 3-540-30732-X

[7] Mark Hankins, “Stand-alone Solar Electric Systems“, Earthscan 2010, ISBN 978-1-84407-713-7

[8] Michael Fette, Rolf Schwarze, Jürgen Voß, “Energieversorgung der Zukunft“, VDE Verlag 1996,

ISBN 3-8007-2174-0

-

Details

- Course title: Energetics of the blast furnace/Paul Wurth

- Number of ECTS: 3

- Course code: MEEE-5

- Module(s): 3.2 MECHANICS

- Language: EN

- Mandatory: No

-

Objectives

Introduction of industrial processes to the students in order to bridge the theory of the study and the industrial application. Technical, environmental and economical aspects are discussed and the interrelationship shall become obvious. -

Course learning outcomes

Understanding of overall iron making procedure and how to reduce its CO2 emissions -

Description

The Blast Furnace Process:- · History and description of the Blast Furnace

- · The Blast Furnace Process:- Reduction Equations- Thermal and mass balance

- · Auxiliary plants (Hot Stoves, Sinter Plant, Pulverized Coal Injection Plant, Slag treatment, etc.) Technical Improvements to the Blast Furnace Process with economical and environmental impacts:

- · Top Gas Recovery Turbine

- · Heat recovery system at the Hot Stoves. Digitalization. Technologies for CO2 emissions reduction- Reducing gas generation- CO2 capture

-

Assessment

T

The students need to accomplish a project. The project presentation and final report will

be considered for the assessment. There are also assignment, which should be submitted in written form.Take-home assignment -5% of Final Grade

Written exam – 75 % of Final Grade

Group work – 20% of Final Grade

-

Note

The students need to accomplish a project. The project presentation and final report would be considered for the assessment. There are also assignment, which should be submitted in written form.

The presentations are shared with the students

-

Details

- Course title: Artificial Intelligence

- Number of ECTS: 5

- Course code: MSP-54

- Module(s): 3.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

- Acquire general knowledge on the objectives and application domains of Artificial Intelligence, the underlying principles behind learning models, decision systems, and problem solving tools.

- Understand the purpose and role of Artificial Intelligence in real life today.

- Compare and contrast various Artificial Intelligence tools and techniques, ranging from search algorithms to deep learning.

- Choose the right tool to solve a given task.

- Evaluate the performance of the applied algorithms and the constructed models based on reliable measures and metrics.

- Acquire general knowledge on the objectives and application domains of Artificial Intelligence, the underlying principles behind learning models, decision systems, and problem solving tools.

-

Course learning outcomes

After attending this class, the students can describe and explain the principles behind the main Artificial Intelligence techniques, tools, models and algorithms.

The students understand the hypotheses and assumptions behind each technique and can reasonably predict the consequences of these assumptions.

The students are capable of choosing the right tool for the job to solve a given problem.

Having chosen the optimal Artificial Intelligence technique, the students can use it to the model the problem efficiently. The students can then implement the model using their preferred programming language, tool, or software.

The students can prepare and pre-process the data related to the problem. The students can identify existing biases and know how to avoid and/or remove them. The students can act correctly to handle missing and/or corrupted data. The students understand the importance of data, and of correct and efficient data gathering techniques.

The students can correctly evaluate the performance of the model using several metrics depending on the task and problem. The students can compare the performance to that of other models. The students can verify if their underlying assumptions are correct. The students are capable of reviewing the effectiveness of the chosen technique and identifying potential improvements.

The students can present the chosen solution, the obtained model, the performance evaluation, and the identified improvements in a precise and concise fashion.

-

Description

The course includes the following topics:

1. General introduction to Artificial Intelligence

2. Problem resolution, search algorithms

3. Games, alpha-beta pruning

4. Meta-heuristics, genetic algorithms, swarm algorithms

5. Constraint programming

6. Markov Decision Processes, reinforcement learning

7. Learning models for regression, classification, clustering

8. Evaluating the performance of a learning model

9. Decision trees, forests

10. Artificial neural networks

11. Unsupervised learning, k-Nearest neighbors, self-organizing maps, growing neural gas

-

Assessment

Pass Criteria:- Student exceeds expectations (excellent) = 20 – 18 points

- Student accomplished task fully as expected = 17.9 – 15 points

- Student shows basic understanding and accomplished task as expected = 14.9 – 12 points

- Students shows basic understanding and can execute the task sufficiently with some flaws = 11.9 – 10 points

Fail Criteria:- Performance is below standard/expectations but student shows some basic knowledge = 9.9 – 8 points

- Performance is below standard/expectations, no basic knowledge of topic/procedure = 7.9 – 0 points

Task 1:

Oral Presentation Resulting from a Group Project (70%)- The students will be divided into groups and will choose one project from a selection. Each project will involve studying a real-world problem and applying the Artificial Intelligence techniques discussed in class in order to solve it. The objective is to gain hands-on experience facing these problems and using these techniques, and to simulate real-world usage of Artificial Intelligence.

- Each group will present the results of the project in a short 5/10-minute start-up pitch-like presentation. The focus of the presentation should be on the design choices made, the assumptions and hypotheses of the solution, the parameter choice and value optimisation, the analysis of the results, the evaluation of solution performance, and the limitations and future improvements envisaged.

- The projects will be assessed using peer-review: each group will evaluate two other projects, different than theirs. This is to get exposures on at least three different problems and solutions. The course coordinator will also participate in the evaluation, and the mark will be the weighted average between the groups and the coordinator. To aid with the peer-evaluation process, the students will receive an evaluation grid along with the project descriptions.

Task 2: Take-home assignments (30%)

The course includes continuous assessment in the form of graded Tutorial exercises.

- Student exceeds expectations (excellent) = 20 – 18 points

-

Note

Literature:

Script, recommended literature in library of UL, exercises, TD, lab sessions

Bishop, C. M. (2006). Pattern recognition and machine learning. springer.

Mitchell, T. M. (1997). Machine learning. 1997. McGraw Hill

Russell, S. J., Norvig, P. (2016). Artificial intelligence: a modern approach. Pearson Education Limited,.

Sutton, R.S., Barto, A.G. (1998). Reinforcement Learning: An Introduction. Cambridge: The MIT Press. (https://muse.jhu.edu/book/60836)

-

Details

- Course title: Artificial Intelligence

- Number of ECTS: 5

- Course code: MSPC-21

- Module(s): 3.3 ELECTRICAL AND COMPUTER ENGINEERING (ECE)

- Language: EN

- Mandatory: No

-

Objectives

Acquire general knowledge on the objectives and application domains of Artificial Intelligence, the underlying principles behind learning models, decision systems, and problem solving tools.

Understand the purpose and role of Artificial Intelligence in real life today.

Compare and contrast various Artificial Intelligence tools and techniques, ranging from search algorithms to deep learning.

Choose the right tool to solve a given task.

Evaluate the performance of the applied algorithms and the constructed models based on reliable measures and metrics. -

Course learning outcomes