About

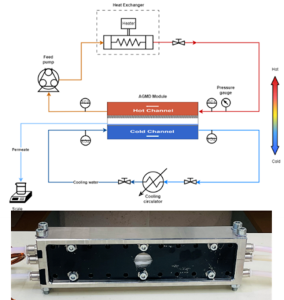

Membrane distillation (MD) is a thermally driven separation process below the boiling point. Evaporation and a hydrophobic membrane are used to separate potable water from sea or brackish water. The salt water is in contact with the membrane. The hydrophobicity prevents the salt water from entering the membrane pores. Water molecules evaporate and are transported by diffusion across the hydrophobic membrane to condense on the other side. The advantage of this technology is that it can be powered by low concentrated solar energy or waste heat. Compared to other desalination technologies, MD has the advantage of low investment and low operating costs. Since the efficiency of MD modules is still comparatively low, the overall goal is to optimize the membrane and module structure to increase efficiency. Direct contact (DCMD) and air-gap (AGMD) membrane distillation are the most common configurations. In the AGMD, unlike the DCMD, there is an air gap between the membrane and the coolant stream, reducing heat losses. The air gap in AGMD provides an additional insulating layer offering advantages regarding the module energy management. On the downside the air gap represents an additional mass transport resistance reducing the freshwater output. The goal of this study is to determine an optimized design for the AGMD system to increase its efficiency, resulting in maximum permeate flow with the least amount of energy consumed. Subsequently various spacer design and hot channel geometries will be assessed and optimize to enhance the permeate flux while minimizing the channel pressure drop and hence the module energy consumption. The findings of the project will foster the design of high-performance flat sheet AGMD modules and can be extend to further module geometries like e.g. spiral wound designs.

Organisation and Partners

Dr. Nikolaos I. Prasianakis (Transport Mechanisms Group, Paul Scherer Institute in Switzerland)

Project team

Prof Stephan LEYER

Full professor in Mechanical engineering – Heat and mass transfer and thermodynamics