Following the recent buzz generated by the Future Horizons conference on “Resilient, Sustainable, and Smart Industrial Solutions” organised by Uni.lu, we’re delighted to spotlight the groundbreaking work of its organiser – Ines Chihi, Assistant Professor in Electrical Measurement and Sensor Technology and the driving force behind the Advanced Engineering & Smart Sensors Solutions research group (AE3S). This dynamic team is at the forefront of developing innovative smart technology solutions—most notably, self-healing sensors. Their recent innovations are drawing increasing attention both within the university and across the wider scientific community.

The importance of sensors: eyes and ears of technology

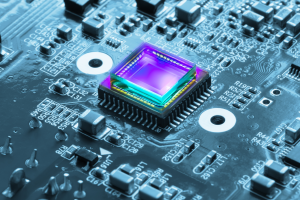

Ines’ research focuses on sensors, which are essentially devices that act as our technological eyes and ears. They detect and measure various aspects of the physical world, such as temperature, pressure, or the presence of dust. They translate real-world observations into data that computers and other smart systems can use. These are immensely important, as they provide the fundamental data that underpins everything, from monitoring our health to ensuring the smooth and safe operation of industrial processes.

As we’ve seen in real-world disasters, when sensors fail, the consequences can be devastating. This can lead to significant financial damage and, the loss of lives. Think about Texas City BP Refinery Explosion (2005), where sensors failed to detect severe pipe corrosion, or the Chevron Refinery Explosion (2012), caused by data drift in the temperature monitoring system. These tragedies highlight the urgent need for more reliable and resilient sensor technologies. This is the exact challenge that the recently funded JUMP project 3D-ENSURE aims to address.

3-D Ensure: Self healing sensors for the future

So, what is 3D-ENSURE? Picture this: sensors that can detect when something is amiss and repair themselves! This is a tangible innovation backed by two hard-earned patents, firmly establishing the value of Ines’ innovation.

Sensor maintenance eats up a staggering 25% to 35% of industrial budgets. By creating sensors that can self-diagnose and self-repair, Prof.Chihi’s team is aiming to drastically reduce these costs, potentially leading to more affordable goods for everyone. It’s like having tiny, tireless, built-in technicians constantly ensuring everything is working perfectly!

‟ Our vision is deeply rooted in creating sustainable and human-centric solutions. Our aim is to develop smart sensor technologies that are not only advanced, but also designed with the well-being of people and the long-term health of our planet in mind.”

Assistant professor in Electrical Measurement and Sensor Technology

Industry’s growing interest

The world of industry is taking notice! The AE3S lab has already received significant interest from various companies eager to embrace this sensor technology. Businesses recognise the value of sensors that provide consistent, accurate, and reliable data, reducing costly downtime and preventing potential catastrophes.

What’s the next exciting chapter in this story? Ines is taking this groundbreaking technology out of the lab and into the real world by launching a spin-off company. This entrepreneurial venture will focus on tailoring and commercialising the sensors, bringing their potential to a wide range of industries.

The 3D-ENSURE project stands as a remarkable example of the cutting-edge, impactful research happening at the University of Luxembourg. With a clear vision and groundbreaking technology, the team isn’t just imagining a smarter future. They’re actively shaping it, one self-healing sensor at a time.

More information

Prof. Ines Chihi leads the research group Advanced Engineering and Smart Sensors Solutions (AE3S) within the Department of Engineering.

-

Advanced Engineering and Smart Sensors Solutions

This project is funded by the FNR JUMP programme.